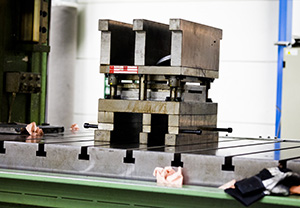

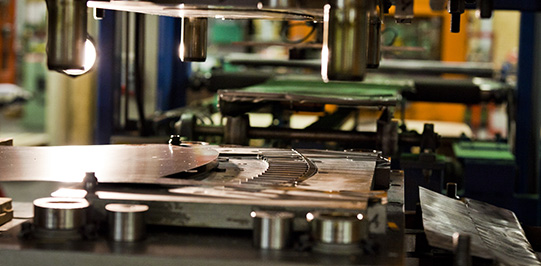

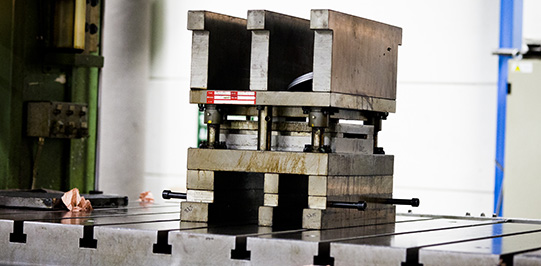

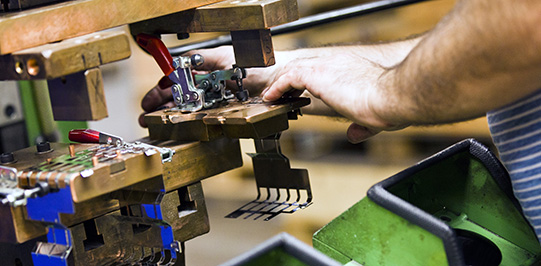

TOOL-RELATED MANUFACTURING

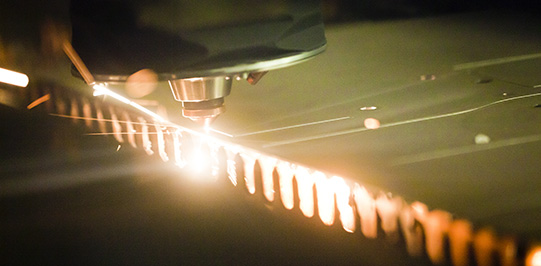

By manufacturing our own tools for sheet metal forming, we have the perfect conditions to offer you processed sheet metal parts of the highest quality with competitive production economics. With the correct equipment and appropriate professional knowledge, this is by far a more economical option than e.g. laser cutting. The method allows for greater capacity, better repeatability, more accurate control and precision. Our mechanical equipment consists of automatic presses, eccentric presses, edging presses and hydraulic presses. We are equipped to find the right solution for highly sophisticated assignments.